Kiwanda cha kutengeneza chips ndogo na kiotomatiki cha kutengeneza viazi

Wazalishaji wa mashine ya chip ya viazi hasa hutoa ndogo na moja kwa moja mistari ya utengenezaji wa chipsi za viazi kutengeneza chips za viazi vya kukaanga.

The ndogo mstari wa uzalishaji wa chipu cha viazi inafaa zaidi kwa uanzishwaji wa awali wa biashara ya uzalishaji wa chips za viazi au kiwanda kidogo cha kutengeneza viazi. Uzalishaji wake ni 50kg/h~500kg/h. Pato la mstari mkubwa wa chip ya viazi ni 300kg/h~2t/h. Ina kiwango cha juu cha automatisering na inafaa kwa viwanda vikubwa vya kutengeneza chips za viazi. Iwapo mashine kubwa au ndogo za kutengeneza chipsi za viazi zina hatua zinazofanana za uzalishaji.

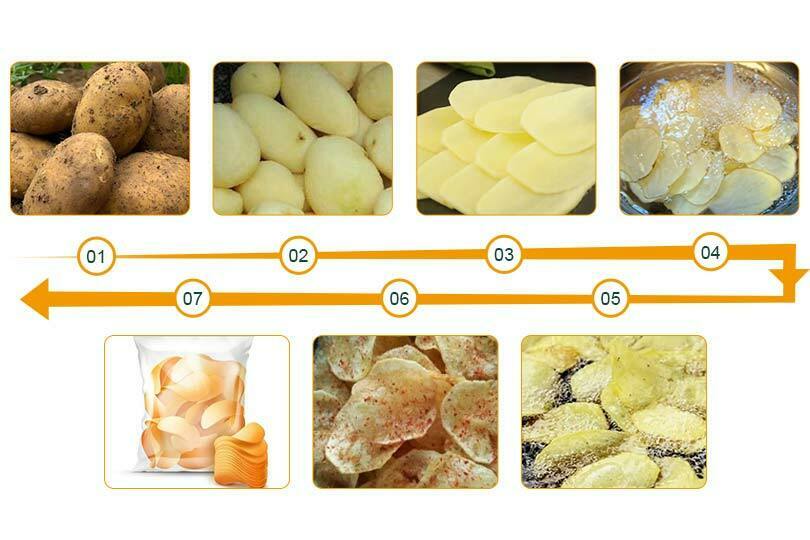

Hiyo ni, kuosha na peeling, slicing, blanching, dehydration, kukaanga, degreasing, seasoning, ufungaji, na hatua nyingine. Mstari wa uzalishaji wa chipu wa viazi unaweza kukidhi mahitaji ya wateja mbalimbali na kuwasaidia kuendeleza biashara ya uzalishaji wa chipsi za viazi.

Utangulizi wa mistari ndogo na kubwa ya viazi

Tofauti kuu kati ya mistari kubwa na ndogo ya uzalishaji wa chip ya viazi ni kiwango cha otomatiki. Hatua za uzalishaji wao ni sawa. Kutokana na kuboreshwa kwa kiwango cha otomatiki, laini ya kuunganisha chipu ya viazi otomatiki inapitisha mashine ya kutengeneza chipu ya viazi yenye pato la juu na otomatiki ya juu.

Ni nini mchakato wa uzalishaji wa chips ya viazi?

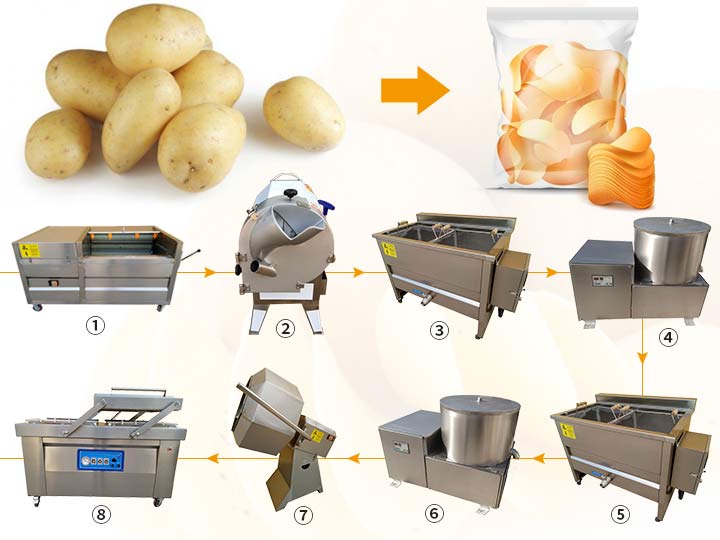

Washer na peeler ---Mkataji---mashine ya blekning ---kipunguza maji---mashine ya kukaanga---deoiling machine -Mashine ya kufungashia, hizi zote ni hatua za kutengeneza chips za viazi.

Kumbuka: Kwa ujumla SUS304 ni chuma cha pua isipokuwa vipengele vya umeme na sehemu maalum zinazohitajika.

Utangulizi wa mstari wa kutengeneza chips ndogo

Chip ya viazi ndogo laini ya utengenezaji ni laini ndogo ya uzalishaji ikilinganishwa na laini ya uzalishaji otomatiki. Inahitaji watu 3-4 kuendesha uzalishaji wote, ambao unafaa zaidi kwa anayeanza katika biashara. Mashine zote zimetengenezwa kwa chuma cha pua.

Je, utayarishaji wa chipsi za viazi huzalisha vipi chips za viazi?

Watu wengi wanapenda kula chips za viazi, na chips za viazi hutengenezwa kutoka kwa viazi. Ina faida fulani kwa mwili, na chips za viazi ladha nzuri, na ni ladha zaidi na mchuzi wa nyanya. Mstari wa uzalishaji wa chips za viazi hutumika mahsusi kwa kutengeneza chips za viazi, kwa hivyo mashine za chipsi za viazi hutengeneza vipi chips za viazi?

Semi-otomatiki mstari wa utengenezaji wa chips za viazi vipengele

- Uwekezaji wa kutengeneza chipsi za viazi nusu otomatiki ni mdogo.

- Ni rahisi kufanya kazi na watu wote wanaweza kuiendesha.

- Mashine hizi za kusindika chips za viazi zimetengenezwa kwa chuma cha pua ambacho kinakidhi mahitaji ya usindikaji wa chakula.

- Ni watu kadhaa tu wanaweza kuendesha laini ya uzalishaji ambayo inaweza kuokoa gharama nyingi za wafanyikazi.

- Mashine imetengenezwa kwa nyenzo za hali ya juu ambazo zina maisha marefu ya huduma.

- Mwongozo wa uendeshaji utaendeshwa na mashine.

200kg/h orodha ya mashine ndogo za kukaanga chips

| Jina | Picha ya mashine | Kigezo |

| Mashine ya kusafisha viazi |  | Mfano: TZ-800 Vipimo: 1600 * 850 * 800mm Voltage: 380v/220v Nguvu: 0.75kw Uzito: 220kg |

| Mkataji wa viazi |  | Mfano: TZ-600 Ukubwa: 750 * 520 * 900mm Uzito: 70KG Nguvu: 0.75KW Uwezo: 600kg / h |

| Mashine ya blanching |  | Mfano: TZ-2000 Ukubwa: 2000*700*950mm Uzito: 300kg Nguvu: 48kw Uwezo: 200kg/h (Njia ya kupokanzwa umeme) |

| Mashine ya kumwagilia |  | Mfano: TZ-400 Ukubwa: 1000500700 mm Uzito: 260KG Nguvu: 1.1kw Uwezo: 300kg / h |

| mashine ya kukaanga chips |  | Mfano :TZ-2000 Size:2000700950 mm Uzito: 300kg Nguvu: 48kw Uwezo: 200kg / h (Njia ya kupokanzwa umeme) |

| mashine ya kuondoa mafuta |  | Mfano: TZ-400 Ukubwa: 1000500700 mm Uzito: 260KG Nguvu: 1.1kw Uwezo: 300kg / h |

| mashine ya kusaga chips |  | Mfano: TZ--800 Uzito: 130kg Nguvu: 1.1kw Uwezo: 300kg / h |

Maelezo ya ndogo mstari wa utengenezaji wa chips za viazi

Mashine ya kuosha viazi - Mashine ya kukata viazi - Mashine ya kukausha viazi - Mashine ya kukausha viazi - Mashine ya kukaangia chips - Mashine ya kukausha viazi - Mashine ya kuweka vitoweo - Mashine ya kupakia chipsi za viazi

Mashine ya kuosha viazi: Mashine hii hutumia brashi kuondoa uchafu kwenye viazi. Haitaharibu viazi na kiwango cha kumenya ni zaidi ya 99%. Mashine hii ina uwezo mkubwa katika mstari wa uzalishaji.

Mashine ya kukata viazi: Mashine hii ni mashine yenye kazi nyingi ambayo inaweza kukata chips za viazi na fries za Kifaransa kwa kubadilisha blade. Uwezo wa mashine hii ni takriban kilo 600 kwa saa. Uso wa mwisho wa bidhaa ni laini.

Mashine ya blanchi ya chipsi za viazi: Mashine hii ina njia kadhaa za kupokanzwa, kama vile joto la gesi, joto la umeme, na kadhalika. Wateja wanaweza kuchagua mashine zinazofaa kulingana na mahitaji yake. Ina mifano kadhaa kwa uwezo tofauti. Joto la maji ni karibu 80 ℃ kwa dakika 1-2.

Mashine ya kumaliza maji ya viazi: Mashine hutumia kanuni ya eccentricity ili kuondoa unyevu kutoka kwa malighafi. Mashine hii ni mashine moja kwa moja yenye ufanisi wa juu.

Mashine ya kukaangia chips za viazi: Viazi za viazi zinahitaji kukaanga baada ya kupunguzwa kwa maji. Hii ni hatua muhimu zaidi ya mstari mzima wa uzalishaji. Joto la kukaanga ni karibu 160-180 ℃ kwa 40-60s. Inaweza kubadilishwa kulingana na mahitaji halisi ya mteja.

Mashine ya kusafisha chip za viazi: Mashine iliyoharibika imetengenezwa kwa chuma cha pua. Ni bora kufunika kifuniko kwa usalama. Mashine hii haitaharibu malighafi wakati wa mchakato wa kufanya kazi.

Mashine ya kuoshea chips viazi: Unaweza kuongeza ladha unayohitaji kwenye mashine. Kwa mfano, spicy, ladha ya nyanya, na kadhalika. Inahitaji kama dakika 2-3 kwa kuchanganya. Pia, wakati wa kuchanganya unategemea uwezo.

Mashine ya kufunga chips za viazi: Mashine hii inajumuisha mifano miwili: chumba kimoja na chumba mbili. Unaweza kuichagua kulingana na uwezo wa chips za viazi. Inaweza kuwa ufungaji wa utupu au la. Athari ya kuziba ya mashine hii ni nzuri sana.

Taarifa Nyingine Kuhusu laini ya uzalishaji wa chips 200kg/h

Matumizi ya mafuta: Gesi/Dizeli

Gesi: Umeme wa 50kw/h na gesi asilia 105Nm³/h au LPG 90kg/h.

Dizeli: Umeme wa 50kw/h na dizeli isiyozidi 80kg/h.

Makadirio ya kiwango cha pembejeo na pato kwa mradi wa chips za viazi

Uwezo wa kuingiza: takriban 600-800kg/h, uwezo wa kutoa: min 200kg/h

Matumizi ya maji: 1.5 tani / h, maji ya kunywa.

Mchoro wa warsha unahitaji kupanga mchakato mzima baada ya Mkandarasi kuwasiliana zaidi na mhandisi wa mnunuzi.

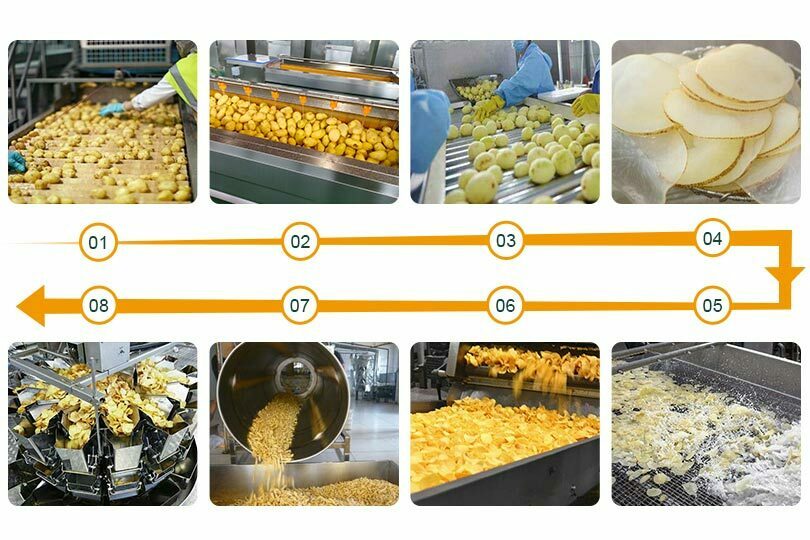

Utangulizi wa laini kubwa ya kutengeneza chips za viazi moja kwa moja

Mstari wa kutengeneza chips otomatiki wa viazi mara nyingi hutumika katika kiwanda kikubwa cha chips za viazi kuzalisha chips za kukaanga. Inatumia mashine za uzalishaji wa juu na otomatiki za usindikaji wa chips za viazi kutengeneza chips za viazi. Hasa, inaunganisha kila mashine ya chip ya viazi kupitia ukanda wa conveyor. Kwa hiyo, mstari wa uzalishaji wa chip ya viazi una kiwango cha juu cha automatisering, pato kubwa la uzalishaji, na uzalishaji wa haraka. Inafaa kwa uzalishaji katika mimea mikubwa ya uzalishaji wa chip za viazi.

Faida za mstari wa usindikaji wa chip moja kwa moja ya viazi

- Mstari wa kuchipua viazi otomatiki una sifa za uwekezaji mdogo wa mara moja, matumizi ya chini ya nishati, utendakazi tofauti, na matengenezo rahisi.

- Ikilinganishwa na laini ya chip ndogo ya viazi, laini ya chip ya viazi otomatiki ina pato la juu na kiwango cha juu cha otomatiki.

- Mashine zote za uzalishaji wa chips za viazi zinaweza kuendeshwa na jopo la kudhibiti akili, ambalo lina kazi ya kuokoa kazi.

- Conveyor ina vifaa vya kubofya kwa kasi ya chini ya hatua, kasi inaweza kubadilishwa kiholela, operesheni ni rahisi, na ufanisi ni wa juu.

500kg/h usanidi wa kina wa chip cha viazi kiotomatiki

| Jina | Picha ya mashine | Kigezo |

| Pandisha |  | Ukubwa: 250010501400 mm Upana wa mkanda: 800 mm Nguvu: 0.75kw Nyenzo: 304 |

| Mashine ya kusafisha viazi |  | Ukubwa: 3600850900 mm Urefu wa roller: 2600 Nguvu: 5.5kw Nyenzo: 304 |

| Mstari wa kuokota |  | Ukubwa: 40001050800 mm Urefu wa mkanda: 800 mm Nguvu: 1.1kw Nyenzo: 304 |

| Mashine ya kukata chips viazi |  | Ukubwa: 600500900 mm Ukubwa wa kukata: 2-9mm Nguvu: 1.5kw Nyenzo: 304 |

| Pandisha |  | Ukubwa: 250010501400 mm Upana wa mkanda: 800 mm Nguvu: 0.75kw Nyenzo: 304 |

| Mashine ya kuosha |  | Ukubwa: 800014501300 mm Upana wa mkanda: 1000 mm Nguvu: 14kw Nyenzo: 304 |

| Mashine ya blanching |  | Ukubwa: 800013501250 mm Upana wa mkanda: 1000 mm Nguvu: 240kw (umeme) Nyenzo: 304 |

| Mashine ya kupoeza |  | Ukubwa: 1000012001100 Upana wa mkanda: 1000 Nambari ya shabiki: vikundi 10 Nguvu: 12kw Nyenzo: 304 |

| Pandisha |  | Ukubwa: 250010501400 mm Upana wa mkanda: 800 mm Nguvu: 0.75kw Nyenzo: 304 |

| Mashine ya kukaanga chips |  | Ukubwa: 1000014501550 Upana wa mkanda: 1000 mm Nguvu: 320 (umeme) Nyenzo: 304 |

| Mashine ya kupoeza |  | Ukubwa: 1000012001100 Upana wa mkanda: 1000 Nambari ya shabiki: vikundi 10 Nguvu: 12kw Nyenzo: 304 |

| Pandisha |  | Ukubwa: 250010501400 mm Upana wa mkanda: 800 mm Nguvu: 0.75kw Nyenzo: 304 |

| Mashine ya viungo |  | Ukubwa: 320010501550 mm Kipenyo cha ngoma: 900mm Urefu wa ngoma: 3000 mm Nguvu: 4kw Nyenzo: 304 |

Utangulizi wa mashine ya kutengeneza chipsi za viazi otomatiki kabisa

Pandisha

Mstari wa chip wa viazi otomatiki, hutumia lifti 4 na ukanda wa kuokota, ambayo hufanya unganisho kati ya mashine mbili kuwa laini. Na inaokoa kazi nyingi.

Mashine ya kusafisha brashi ya ond

Mstari huu wa utengenezaji wa chips za viazi otomatiki, hutumia mashine ya kusafisha ond brashi badala ya mashine ya kusafisha brashi kwenye laini ndogo ya uzalishaji. Mashine ya kusafisha ond katika brashi ya ond husafirisha viazi kiatomati, wakati brashi huondoa ngozi ya viazi. Wakati viazi husafirishwa kutoka mwanzo hadi mwisho, itasafishwa.

Mashine ya kuosha chips za viazi

Baada ya kukatwa na kipande cha viazi, itasafishwa na mashine ya kuosha. Katika mstari wa uzalishaji wa chipu wa viazi otomatiki, kwa vile vyote vinabadilishwa na mashine, huongeza hatua ya kusafisha ili kuhakikisha kuwa chips za viazi ni safi na nadhifu.

Chips blanching na kukaranga

Mashine ya kukaanga na kukaangia viazi hupitisha mashine ya kukaanga na kukaangia yenye ujazo mkubwa. Njia zao za kupokanzwa ni inapokanzwa umeme na inapokanzwa hewa. Urefu wa mashine inayoendelea ya kukaanga na kukaanga inaweza kubinafsishwa kulingana na utengenezaji wa chips za viazi na mahitaji ya mteja. Zaidi ya hayo, kikaango kinachoendelea kinaweza kuandaa vifaa kama vile chujio cha mafuta ya tank ya kuhifadhi mafuta ili kuchuja mafuta.

Mashine ya kitoweo cha chips

Laini kubwa ya uzalishaji wa chipu cha viazi kiotomatiki kwa kawaida hutumia mashine ya kuoshea ngoma ili kuonja chips za viazi. Mashine ya kitoweo cha ngoma inaweza kuunganishwa kwenye kipoza kwa ajili ya kusafirisha bila kukatizwa na kuweka viungo.

Mashine ya kufungashia chips za viazi

Hakuna mashine ya kupakia chipu ya viazi iliyoorodheshwa kwenye laini kubwa ya chipu ya viazi kwa sababu wateja wanaweza kuwa na chaguo tofauti. Shuliy hutoa hasa mashine za kufungashia chips za viazi na mizani ya ndoo, na ina mizani ya ndoo mbili, mizani ya ndoo nne, mizani ya ndoo nane, na aina zingine za mashine za ufungaji. Sio bidhaa isiyo ya kawaida, tunaweza kubinafsisha mashine ya ufungaji ya chip ya viazi kulingana na saizi ya kifungashio cha mteja, mtindo na mahitaji mengine.

Huduma Yetu Kuhusu laini ya utengenezaji wa chips za viazi

Ndiyo, tuko. Karibu utembelee kiwanda chetu.

Ndiyo, tunaweza.

Mhandisi wetu anaweza kwenda nje kusakinisha na kuwafunza wafanyakazi wako kuendesha laini kamili ya mashine.

Mwaka 1 isipokuwa kwa vipuri vinavyoweza kutumika.

Tutasambaza mashine ndani ya siku 30.

Maswali Yanayoulizwa Mara kwa Mara kuhusu kutengeneza chips za viazi

Jinsi ya kuanza biashara ya chipsi za viazi?

Ikiwa unaanza biashara ya uzalishaji wa chips za viazi kwa mara ya kwanza, basi tunapendekeza uangalie soko kwanza. Unaweza kuona ukubwa wa chips maarufu wa viazi na vipimo vya ufungaji katika soko lako la ndani. Na unaweza kukadiria kidogo gharama ya kuanzisha biashara ya chipsi za viazi. Baada ya kuamua faida, unaweza kununua biashara ya uzalishaji wa chips za viazi kutoka kwa mtengenezaji wa mashine ya uzalishaji wa viazi kwa ajili ya uzalishaji.

Mashine ya Zhengzhou Taizy imesafirisha mashine hii kwa nchi nyingi za kigeni. Tuna wafanyakazi wenye uzoefu na wahandisi. Tunaweza kutoa huduma isiyo na lawama kabla ya mauzo na huduma ya baada ya mauzo. Mshauri wetu wa mauzo anaweza kutoa maelezo ya kina kwenye mashine hii. Ikiwa unataka mashine hii, pls wasiliana nasi!