Линия по производству картофеля фри и индейки производительностью 50–2000 кг.

The french fries production line is a good assistant for the production of French fries. It helps small and large potato chip processing plants to make chips. The complete set of french fries production lines consists of a potato cleaning and peeling machine, potato cutter machine, blanching machine, dehydration machine, frying machine, deoiling machine, seasoning machine, packaging machine, and auxiliary equipment.

Производительность всего оборудования для производства картофеля фри может достигать 50 кг/ч ~ 2 т/ч. Он имеет такие преимущества, как низкие единовременные инвестиции, низкое энергопотребление, множество функций, небольшой размер, высокая прибыль, удобное использование и обслуживание и т. д.

Внедрение линии по производству картофеля фри

Линия по производству картофеля фри имеет полуавтоматические и полностью автоматические производственные линии. Небольшая полуавтоматическая линия по производству картофеля фри в основном состоит из полуавтоматических машин для переработки картофеля. Он требует ручного управления машиной, имеет низкие инвестиционные затраты и занимает меньше площади. Его производительность варьируется от 50 кг/ч до 500 кг/ч.

Полностью автоматическая линия по производству картофеля фри отвечает потребностям крупных заводов по производству картофеля фри. Для переработки картофеля в картофель фри используется крупномасштабное автоматизированное оборудование для переработки картофеля. Крупномасштабная линия по производству картофеля фри занимает большую площадь, инвестиционные затраты высоки, а производственная мощность велика. Производительность полностью автоматической линии для приготовления картофеля фри составляет 300–2 т/ч.

Применение линии по производству картофеля фри

This french fries machine is not only suitable for french fries, but also for the production of potato chips. Multiple choices for the customer, they can produce the product according to the market demand. Frozen french fries can be produced by this line. According to the customer’s feedback, all the machines have been improved over the years. The technology of producing the machines is very mature which minimized production costs to increase the client’s sales interest.

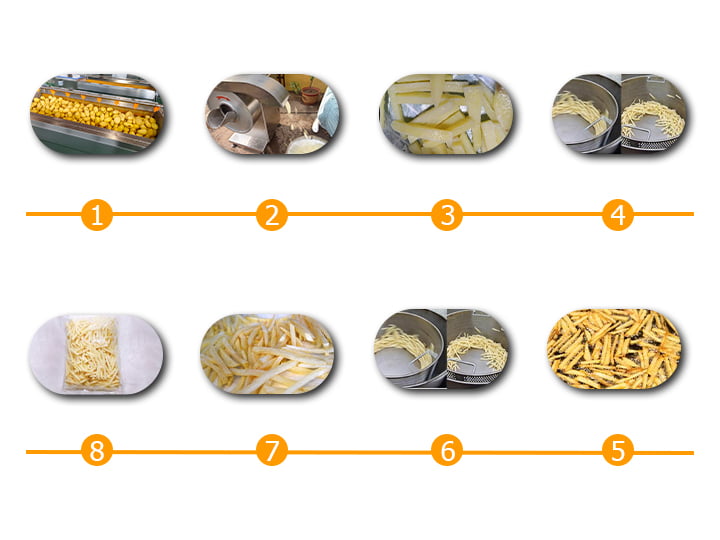

Технологический процесс приготовления картофеля фри

Очистка и очистка - сбор - нарезка полосками - бланширование - обезвоживание - жарка - обезжиривание - сушка на воздухе - замораживание - упаковка - охлаждение - продажа

Примечание. Автоматические линии по производству картофеля фри/чипсов в целом одинаковы, различаются только машины, используемые для нарезки.

Небольшая линия по производству замороженного картофеля фри

Небольшая линия по производству картофеля фри в основном производится на полуавтоматических машинах для производства картофеля фри. Производительность небольшой линии по производству картофеля фри составляет 50–500 кг/ч. Способ нагрева имеет электрический нагрев и газовый нагрев.

Этапы производства небольшой линии по производству картофеля фри

- Сначала в ящик кладут картофель. Стиральная машина. стиральная машина удалит грязь с поверхности картофеля. А дырочки на картофеле не ускользнут от волшебных когтей стиральной машины.

- Далее очищенный картофель автоматически перекладывается на стриппер или слайсер. Стрипперные машины Картофель нарежем тонкими полосками, размер картофеля фри обычно 7*7 мм.

- Третий шаг будет автоматически перенесен на промывочную машину. Дайте чипсам или картофельным полоскам остыть, и зря приступайте к следующему процессу.

- На четвертом этапе вымытый картофель будет переложен в Машина для обезвоживания. Это позволит деталям на поверхности картофеля быстро высохнуть. Это также необходимо для предотвращения разбрызгивания масла наружу во время процесса жарки и уменьшения его использования.

- На пятом этапе сушеный картофель будет транспортирован в Фритюрница. Температура жарки составляет 170 градусов по Цельсию, время жарки составляет от 3 до 5 минут. Жареный картофель блестит.

- Шестой шаг пройдет Машина для удаления масла. Конструкция машины для удаления масла и принцип работы дегидратора одинаковы, за исключением того, что в одну заливается масло, а в другую — вода.

- На седьмом этапе картофель будет перенесен в морозильную машину для заморозки на случай, если картофель фри слипнется.

- Наконец, картофель фри или картофельные чипсы будут упакованы и отправлены на склад.

Технические параметры полуавтоматической линии для картофеля фри производительностью 50 кг/ч

| Имя машины | Картина | Подробности |

| Машина для мойки и очистки картофеля |  | Модель: ТЗ-800 Производительность: 700 кг/ч Размер: 1580*850*800 мм Напряжение: 220 В, 50 Гц Мощность: 1,5 кВт Вес: 180 кг Одна партия: 2 минуты Материал: нержавеющая сталь 304. Ролики: 9 шт. Машина с колесами, распылителями и поддоном для воды. |

| машина для резки картофеля фри |  | Модель: ТЗ-600 Производительность: 600 кг/ч Размер: 950*800*950 мм Напряжение: 220 В, 50 Гц мощность: 1,1 кВт Вес: 110 кг Материал: нержавеющая сталь 304. |

| машина для бланширования картофельных полосок |  | Модель: ТЗ-500 Мощность: 12 кВт Напряжение: 220 В, 50 Гц вес: 70 кг размер: 700*700*950 мм Тип отопления: Электрический Производительность: 50 кг/ч Материал: нержавеющая сталь 304. Одна партия: 1-2 минуты Удалить крахмал |

| дегидратор |  | Модель: ТЗ-400 Производительность: 300 кг/ч Размер: 1000*500*700 мм Напряжение: 220 В, 50 Гц мощность: 1,5 кВт Вес: 360 кг Материал: нержавеющая сталь 304. Время: 1-3 минуты |

| машина для жарки картофеля фри |  | Модель: ТЗ-500 Мощность: 12 кВт Напряжение: 220 В, 50 Гц вес: 70 кг размер: 700*700*950 мм Тип отопления: Электрический Производительность: 50 кг/ч Материал: нержавеющая сталь 304. |

| машина для обезжиривания |  | Модель: ТЗ-900 Производительность: 200 кг/ч Размер: 1100*500*850 мм Напряжение: Напряжение: 220 В, 50 Гц Мощность: 1,5 кВт Вес: 350 кг Материал: нержавеющая сталь 304. |

| морозильная камера для замороженного картофеля фри |  | Модель: ТЗ-650 Объем: 650 л Слой: 20 слоев Минимальная температура:-45℃ Размер лотка: 400*600 мм Производительность: 200-300 кг/ч Замораживающая среда: Р-404А Конденсатор: воздушное охлаждение Мощность: 5,5 кВт Внутренняя размер: 1170*615*1019 мм Размер: 1400*1142*1872мм Вес: 490 кг Материал: нержавеющая сталь 304. |

| упаковочная машина для картофеля фри |  | Модель: TZ300 Мощность: 1,5 кВт Напряжение: 380 В, 50 Гц вес: 260 кг размер:1200*600*850 мм Производительность: 300 кг/ч Материал: нержавеющая сталь 304. |

Преимущества полуавтоматической линии по производству картофеля фри

- Машина для приготовления картофеля фри на линии по производству картофеля фри имеет простую конструкцию, небольшую площадь и низкие инвестиционные затраты.

- Все полуавтоматические машины для картофеля фри изготовлены из нержавеющей стали 304, которая устойчива к коррозии и долговечна.

- Фритюрница для картофеля фри на производственной линии и бланшировальная машина оснащены электрическим нагревом и воздушным нагревом. Клиентам удобно выбирать подходящие способы отопления для местных теплоресурсов.

- Кроме того, фритюрница и бланшировальная машина оснащены высококачественными бесшовными нагревательными трубками, которые обеспечивают безопасность производства.

- Эта небольшая линия по производству картофеля фри подходит для первоначальных инвесторов или небольших предприятий по производству картофеля фри с ограниченными капитальными площадками.

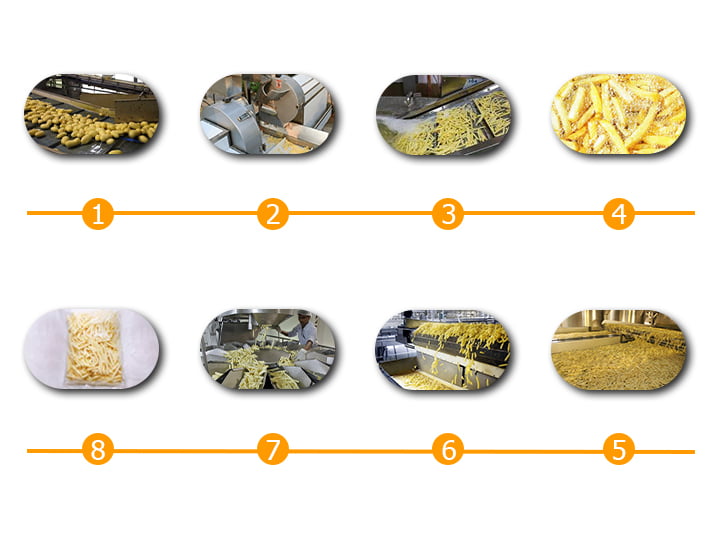

Полностью автоматический завод по переработке картофеля фри

Автоматический завод по производству картофеля фри в основном состоит из автоматизированных машин по переработке картофеля. Эта полностью автоматическая линия для приготовления картофеля фри использует интеллектуальную цифровую систему управления для контроля всего процесса производства картофеля фри. Производительность крупномасштабной автоматической линии по производству картофеля фри составляет 300–2 т/ч. Его также можно отапливать электричеством и газовым отоплением.

Полностью автоматическая линия по производству картофеля фри. Этапы производства

- Сначала используйте конвейерную ленту, чтобы перенести картофель в машину для очистки спиральной щетки.

- Машина для очистки спиральной щетки автоматически очищает очищенный картофель, при этом картофель выдвигается вперед и выгружается под действием спирали.

- Вымытый картофель собирается вручную при прохождении через конвейерную ленту.

- Машина для нарезки картофеля фри нарезает картофель на полоски одинакового размера, а диапазон размеров нарезки машины составляет 3–12 мм.

- Полоски картофеля подаются по конвейерной ленте в машину для очистки ворса для удаления и отбора примесей.

- Отобранные картофельные чипсы очищаются в стиральной машине.

- Затем полоски картофеля бланшируются на машине непрерывного бланширования для удаления излишка крахмала в картофеле.

- После сушки на воздухе с помощью вибрационной обезвоживающей машины и воздушной сушилки поместите во фритюрницу для жарки.

- Фритюрница непрерывного действия с двухслойной сетчатой лентой позволяет контролировать температуру и время жарки.

- Жареный картофель фри сушится на воздухе с помощью виброобезжиривателя и воздушной сушилки.

- Картофель фри необходимо заморозить в морозильной камере перед упаковкой, чтобы предотвратить слипание.

- Наконец, упакуйте картофель фри в пакет с помощью автоматической упаковочной машины для картофеля фри.

Параметры большой автоматической установки по переработке картофеля фри производительностью 300 кг/ч

| Имя машины | Картина | Параметр |

| подъемник |  | Мощность: 0,55 кВт Напряжение: 380 В/50 Гц Размер: 1500x800x1600 мм Скорость ленты: регулируемая Марка двигателя: Сименс Материал: 304 СУС Ремень: ПВХ |

| шнековая машина для очистки картофеля |  | Мощность: 4,37 кВт Напряжение: 380 В/50 Гц Размер:3100x900x1500 мм Скорость внутреннего винта: регулируемая Марка двигателя: Сименс Материал: 304 СУС |

| линия комплектования |  | Мощность: 0,75 кВт Напряжение: 380 В/50 Гц Размер3000*800*900 мм Скорость ленты: регулируемая Марка двигателя: Сименс Материал: 304 СУС |

| электрический резак для картофельных чипсов |  | Мощность: 1,1 кВт Напряжение: 380 В/50 Гц Вес: 120 кг Размер:700700950 мм Марка двигателя: Сименс Материал: 304 СУС |

| подъемник |  | Мощность: 0,75 кВт напряжение: 380 В/50 Гц Вес: 330 кг Размер:1500*800*1500 мм Скорость ленты: регулируемая Марка двигателя: Сименс Материал: 304 СУС |

| машина для удаления валиков для волос |  | Размер:2400*1000*1300 мм Мощность: 1,1 кВт Напряжение: 380 В/50 Гц Марка двигателя: Сименс Материал: 304 СУС |

| ополаскивающая машина |  | Мощность: 2,95 кВт Напряжение: 380 В/50 Гц Размер:3500x1200x1300 мм Марка двигателя: Сименс Материал: 304 СУС |

| Машина непрерывного бланширования картофеля фри |  | Мощность: 60 кВт Напряжение: 380 В/50 Гц Вес: 1400 кг Размер: 4000x1200x1400 мм Горелка: Италия Риелло Отопление: дизельное Материал: 304 СУС |

| вибрационный очиститель воды |  | Мощность: 0,5 кВт Напряжение: 380 В/50 Гц Размер:1800*1000*900 мм Марка двигателя: Сименс Материал: 304 СУС |

| машина воздушного охлаждения |  | Мощность: 7,5 кВт Напряжение: 380 В/50 Гц Размер: 3500x1200x1400 мм Мощность вентилятора: 0,75 кВт*10 шт. Давление ветра: 120 Па Скорость: 2800 об/мин Материал: 304 СУС |

| подъемник |  | Мощность: 0,75 кВт Напряжение: 380 В/50 Гц Вес: 180 кг Размер:1500*800*1300 мм Материал: 304 СУС |

| Промышленная машина для жарки картофеля фри |  | Мощность: 80 кВт напряжение: 380 В/50 Гц Размер: 4000x1200x2400 мм Марка горелки: Италия liya road Отопление:дизельное 260 000 ккал Двигатель: Siemens Контроллер: Schneider Материал: 304 СУС |

| масляный бак |  | Диаметр: 1,2 м. Высота: 1,5 м. Сырье: нержавеющая сталь 304 |

| средство для удаления вибрационного масла |  | Мощность: 0,5 кВт Напряжение: 380 В/50 Гц Размер:1500*1000*1300 мм Мотор: Сименс Материал: 304 СУС |

| охладитель воздуха |  | Мощность: 7,5 кВт Напряжение: 380 В/50 Гц Размер: 3500x1200x1400 мм Мощность вентилятора: 0,75 кВт*10 шт. Давление ветра: 120 Па Скорость: 2800 об/мин Материал: 304 СУС |

| подъемник |  | Мощность: 0,75 кВт Напряжение: 380 В/50 Гц Вес: 500 кг Размер: 2000x800x2200 мм Материал: 304 СУС |

| морозильная камера непрерывного действия для картофеля фри |  | Размер:1100030002600 мм Ширина сетчатого ремня: 1500 мм. Вентилятор из нержавеющей стали: 6*1,5 кВт Мотор с сетчатым ремнем: Siemens ПЛК: Сименс СУС 304 Толщина внутренней коробки: 0,8 мм внешняя толщина: 0,8 мм Внутренняя изоляция хлопок; 120 мм. Марка компрессора: Германия Bitzer Материал: 304 СУС |

Features of the automatic French fries production line:

- Автоматическая линия по производству картофеля фри экономит рабочую силу, и для работы всей линии требуется всего четыре-пять человек.

- Производство картофеля фри по низкой себестоимости. Сырьем является картофель по низкой цене, а переработка обходится быстрее.

- Машина для обработки чипсов использует энергосберегающий двигатель для экономии электроэнергии и снижения производственных затрат.

- Вся линия по производству картофеля фри имеет низкий расход топлива и регулируемую температуру жарки.

- Capacity: fully automatic production line output of 300-1000 kg matches the suitable machine according to customer needs.

- Расширенная механическая конфигурация и управление машиной для приготовления картофеля фри. Он всегда может поддерживать безопасное рабочее состояние, что не только улучшает производительность, но и делает качество продукции стабильным. Цвет, аромат и вкус конечного продукта едины.

- Автоматическая фильтрация фритюрницы непрерывного действия на производственной линии может значительно продлить срок службы масла. Нет необходимости часто менять масло. Масло, потребляемое в процессе жарки продукта, эквивалентно маслу, поглощенному продуктом, и его использование значительно улучшается.

- Усовершенствованная и эффективная система отопления позволяет избежать потерь энергии и значительно экономит энергозатраты. Непрерывная работа производственной линии повысила эффективность работы, эффективно снизила затраты, а также очень полезна для затрат на рабочую силу и управления.

- Использование этого оборудования позволяет значительно улучшить качество продукции, снизить различные затраты в производственном процессе и сделать продукцию более конкурентоспособной на рынке.

Automatic frozen chips plant particularly Processing

- Цена (с точки зрения цены наша цена более выгодна в той же отрасли. Если объем вашей покупки относительно велик, мы также предоставим вам некоторые скидки от исходной цены)

- Срок использования (при правильном обслуживании срок использования составляет от 5 до 6 лет)

- Эффективность работы: высокая производительность в единицу времени: 200–500 кг/ч, 500–800 кг/ч, 800–1000 кг/ч. Мы можем оборудовать механическое оборудование различной мощности в соответствии с различными потребностями клиентов)

- Емкость (300~1000 кг)