容量50kg-2000kgのフライドポテト生産ライン七面鳥

フライドポテトの生産ラインは、フライドポテトの生産に優れたアシスタントです。大小のポテトチップ加工プラントがチップを作るのに役立ちます。フライドポテトの生産ラインの完全なセットは、ポテトクリーニングとピーリングマシン、ジャガイモカッターマシン、ブランチングマシン、脱水機、フライドマシン、デオイル機、調味料、パッケージングマシン、補助装置で構成されています。

フライドポテト製造機のセット全体の容量は50kg / h〜2t / hに達することができます。一回限りの投資が安い、エネルギー消費が少ない、機能が多い、小型、収益性が高い、使用が便利、メンテナンスが簡単などの利点があります。

フライドポテト製造ラインのご紹介

フライドポテトの生産ラインには、半自動と全自動の生産ラインがあります。小型半自動フライドポテト生産ラインは、主に半自動ジャガイモ加工機で構成されています。機械の手動操作が必要であり、投資コストが低く、床面積も小さくて済みます。出力範囲は50kg/hから500kg/hです。

全自動フライドポテト生産ラインは、大規模なフライドポテト工場のニーズに応えます。大型の自動ジャガイモ加工設備を用いてジャガイモをフライドポテトに加工します。大規模なフライドポテト生産ラインは広い面積をカバーし、投資コストが高く、生産能力が大きい。全自動フライラインの出力範囲は300kg/h~2t/hです。

フライドポテト生産ラインの応用

このフライドポテトマシンは、フライドポテトだけでなく、ポテトチップスの生産にも適しています。 顧客の複数の選択肢は、市場の需要に応じて製品を生産できます。フローズンフライドポテトは、このラインで生産できます。顧客のフィードバックによると、すべてのマシンは長年にわたって改善されてきました。マシンを生産する技術は非常に成熟しており、クライアントの売上利益を増やすために生産コストを最小限に抑えます。

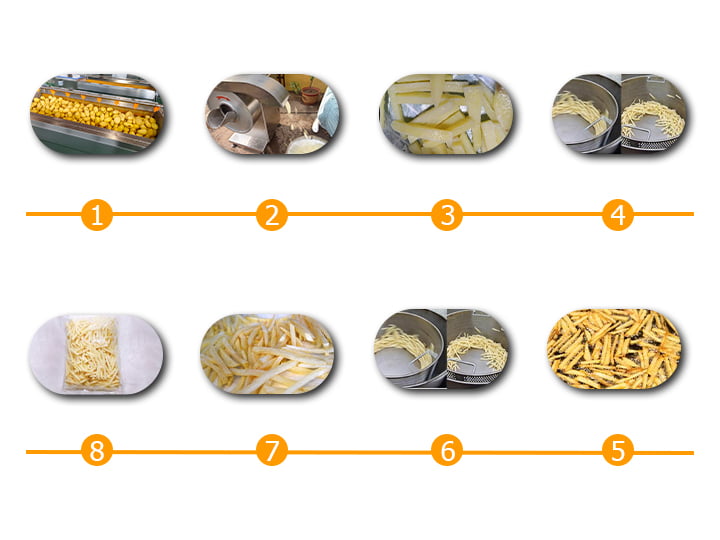

フライドポテトの工程の流れ

洗浄・皮むき - ピッキング - 短冊切り - 湯通し - 脱水 - フライ - 脱油 - 風乾 - 冷凍 - 包装 - 冷蔵 - 販売

注: 自動フライドポテト/チップス生産ラインは一般的に同じですが、スライスに使用される機械のみが異なります。

小規模冷凍フライドポテト製造ライン

小型フライドポテト生産ラインは主に半自動フライドポテト生産機によって生産されます。小型フライドポテトラインの生産量は50kg/h〜500kg/hです。加熱方式には電気加熱とガス加熱があります。

小型フライドポテトラインの製造手順

- まずはジャガイモを入れます 洗濯機。洗濯機はジャガイモの表面の汚れを取り除きます。そして、ジャガイモの小さな穴は洗濯機の魔法の爪から逃れることはできません。

- 次に、皮をむいたジャガイモは自動的にストリッパーまたはスライサーに移されます。 ストリッパーマシン ジャガイモを薄いストリップに切ります。フライドポテトのサイズは通常7*7mmです。

- 3 番目のステップは自動的に The Rinsing Machine に転送されます。ポテトチップスやポテトストリップを風呂に入れて、無駄に次の工程に進みます。

- 4番目のステップでは、洗ったジャガイモを 脱水機。こうすることでジャガイモの表面の部分が早く乾燥します。揚げる際に油が外に飛び散るのを防ぎ、油の使用量を減らすためでもあります。

- 5番目のステップでは、風乾したジャガイモが次の場所に輸送されます。 フライヤーマシン。 揚げ温度は170℃、揚げ時間は3~5分程度です。フライドポテトが光ってます。

- 6番目のステップが実行されます 油分除去機です。 油除去機のエンジニアリングと脱水機の動作原理は、油を入れるのと水を入れる点を除いて同じです。

- 7 番目のステップでは、フライド ポテトがくっついた場合に備えて、ジャガイモを冷凍機に移して冷凍します。

- 最後に、フライドポテトまたはポテトチップスが包装されて倉庫に入れられます。

50kg/h半自動フライドポテトラインの技術パラメータ

| マシン名 | 写真 | 詳細 |

| ジャガイモ洗浄皮むき機 |  | モデル: TZ-800 能力: 700kg/h 寸法: 1580*850*800 ミリメートル 電圧: 220v、50hz 電力: 1.5kw 体重:180kg 1バッチ:2分 材質: 304 ステンレス鋼 ローラー: 9個 ホイール、スプレー、水トレイ付きの機械。 |

| フライドポテトカッターマシン |  | モデル: TZ-600 能力:600kg/h 寸法:950*800*950mm 電圧 : 220v、50hz 電力: 1.1kw 体重:110kg 材質: 304 ステンレス鋼 |

| ポテトストリップ湯通し機 |  | モデル: TZ-500 パワー:12kw 電圧:220v、50hz 体重:70kg サイズ:700*700*950mm 加熱タイプ: 電気 能力: 50kg/h 材質: 304 ステンレス鋼 1バッチ:1~2分 でんぷんを取り除く |

| 脱水機 |  | モデル: TZ-400 能力:300kg/h サイズ:1000*500*700mm 電圧 : 220v、50hz 電力:1.5kw 重量: 360kg 材質: 304 ステンレス鋼 時間: 1~3分 |

| フライドポテトフライ機 |  | モデル: TZ-500 パワー:12kw 電圧:220v、50hz 体重:70kg サイズ:700*700*950mm 加熱タイプ: 電気 能力: 50kg/h 材質: 304 ステンレス鋼 |

| 脱油機 |  | モデル: TZ-900 能力:200kg/h 寸法:1100*500※850mm 電圧:電圧:220v、50hz 電力: 1.5kw 重量: 350kg 材質: 304 ステンレス鋼 |

| 冷凍フライドポテト冷凍庫 |  | モデル: TZ-650 容量:650L レイヤー:20レイヤー 最低気温:-45℃ トレイサイズ:400*600mm 能力: 200-300kg/h 凍結媒体: R-404A コンデンサー: 空冷 パワー:5.5kwインナー サイズ:1170*615*1019mm アウトサイズ:1400*1142*1872mm 重量: 490kg 材質: 304 ステンレス鋼 |

| フライドポテト包装機 |  | モデル: TZ300 電力:1.5kw 電圧:380v、50hz 重量: 260kg サイズ:1200*600※850mm 能力:300kg/h 材質: 304 ステンレス鋼 |

半自動フライドポテト加工ラインのメリット

- 小型フライドポテトラインのフライドポテトマシンは構造が簡単で、面積が小さく、投資コストが低いです。

- すべての半自動フライドポテトマシンは、耐腐食性と耐久性に優れたオール304ステンレス鋼で作られています。

- 生産ラインのフライドポテトフライヤーと湯通し機には電気加熱方式と空気加熱方式があります。地域の熱源に適した加熱方法を選択できるため、顧客にとって便利です。

- また、フライヤーと湯通し機には高品質の継ぎ目のない加熱管を採用しており、生産時の安全性を確保しています。

- この小規模フライドポテトラインは、初期投資家や資本拠点が限られている小規模フライドポテト生産工場に適しています。

全自動フライドポテト加工プラント

自動フライドポテト製造プラントは、主に自動ポテト加工機で構成されています。この全自動フライドポテト ラインは、インテリジェントなデジタル制御システムを使用して、フライドポテトの製造プロセス全体の動作を制御します。大規模フライドポテト自動ラインの生産量は300kg/h~2t/hです。電気やガスによる暖房も可能です。

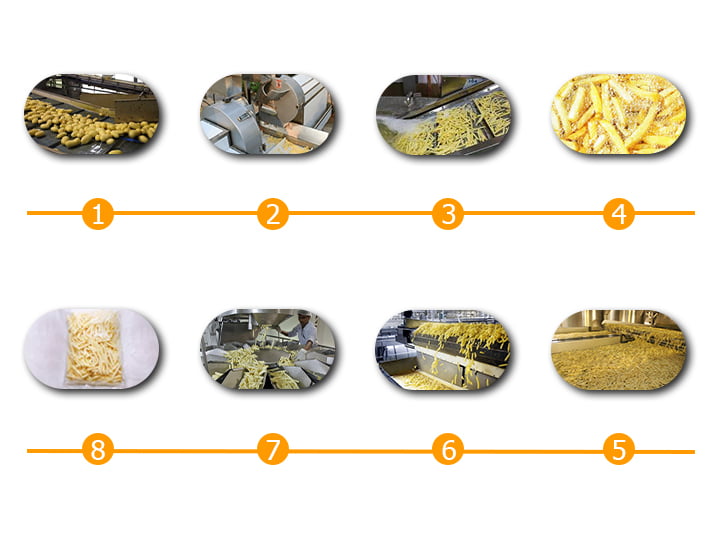

全自動フレンチフライ生産ラインの生産手順

- まず、ベルトコンベアを使ってジャガイモをスパイラルブラシ洗浄機に移します。

- スパイラルブラシ洗浄機は皮をむいたジャガイモを自動的に洗浄し、スパイラルの作用でジャガイモが前方に押し出されて排出されます。

- 洗ったジャガイモはベルトコンベアを通過しながら手作業で取り出されます。

- フライドポテト切断機はジャガイモを同じサイズのポテトストリップに切断します。フライドポテト切断機の切断サイズ範囲は3〜12mmです。

- ポテトストリップはコンベアベルトによって糸くずローラー洗浄機に運ばれ、不純物の除去と選別が行われます。

- 選りすぐりのポテトチップスを洗浄機で洗浄

- 次に、ジャガイモのストリップを連続湯通し機で湯通しし、ジャガイモ内の余分なデンプンを除去します。

- 振動脱水機、エアードライヤーで風乾した後、フライヤーに入れて揚げます。

- 二重層メッシュベルトを備えた連続フライドフライヤーは、揚げる温度と時間を制御できます。

- 揚げたフライドポテトを振動脱脂機とエアードライヤーで自然乾燥させます。

- フライドポテトは接着を防ぐため、包装する前に冷凍庫で冷凍する必要があります

- 最後にフライドポテト自動包装機でフライドポテトを袋に包装します。

300kg/h大型自動フライドポテト加工プラントパラメータ

| マシン名 | 写真 | パラメータ |

| ホイスト |  | 電力:0.55kw 電圧:380v/50Hz サイズ:1500x800x1600mm ベルト速度: 調整可能 モーターブランド: シーメンス 材質:304SUS ベルト:PVC |

| スクリュージャガイモ洗浄機 |  | パワー:4.37kw 電圧:380v/50Hz サイズ:3100x900x1500mm 内側のネジ速度: 調整可能 モーターブランド: シーメンス 材質:304SUS |

| ピッキングライン |  | 電力:0.75kw 電圧:380v/50Hz サイズ3000*800※900mm ベルト速度: 調整可能 モーターブランド: シーメンス 材質:304SUS |

| 電動ポテトチップスカッター |  | 出力:1.1kw 電圧:380v/50Hz 重量:120kg サイズ:700700950mm モーターブランド: シーメンス 材質:304SUS |

| ホイスト |  | 電力:0.75kw 電圧:380v/50hz 重量:330kg サイズ:1500*800※1500mm ベルト速度: 調整可能 モーターブランド: シーメンス 材質:304SUS |

| ヘアローラーリムーバーマシン |  | サイズ:2400*1000※1300mm 電力:1.1kw 電圧:380v/50hz モーターブランド: シーメンス 材質:304SUS |

| すすぎ機 |  | 出力:2.95kw 電圧:380v/50Hz サイズ:3500x1200x1300mm モーターブランド: シーメンス 材質:304SUS |

| 連続フライドポテト湯通し機 |  | パワー:60kw 電圧:380v/50Hz 重量:1400kg サイズ:4000x1200x1400mm バーナー:イタリア リエロ 暖房: ディーゼル 材質:304SUS |

| 振動水除去剤 |  | 電力:0.5kw 電圧:380v/50Hz サイズ:1800*1000※900mm モーターブランド: シーメンス 材質:304SUS |

| 空冷機 |  | パワー:7.5kw 電圧:380v/50Hz サイズ:3500x1200x1400mm ファン出力:0.75kw*10 個 風圧:120pa 速度:2800r/分 材質:304SUS |

| ホイスト |  | 電力:0.75kw 電圧:380v/50hz 重量:180kg サイズ:1500*800※1300mm 材質:304SUS |

| 工業用フライドポテトフライ機 |  | パワー:80kw 電圧:380v/50Hz サイズ:4000x1200x2400mm バーナーブランド:イタリアリヤロード 暖房:ディーゼル 260,000kcal モーター: シーメンス コントローラー: シュナイダー 材質:304SUS |

| オイルタンク |  | 直径:1.2m 高さ:1.5m 原材料:304SS |

| 振動オイルリムーバー |  | 電力:0.5kw 電圧:380v/50Hz サイズ:1500*1000※1300mm モーター: シーメンス 材質:304SUS |

| エアクーラー |  | パワー:7.5kw 電圧:380v/50Hz サイズ:3500x1200x1400mm ファン出力:0.75kw*10 個 風圧:120pa 速度:2800r/分 材質:304SUS |

| ホイスト |  | 電力:0.75kw 電圧:380v/50hz 重量:500kg サイズ:2000x800x2200mm 材質:304SUS |

| 連続フライドポテト冷凍庫 |  | サイズ:1100030002600mm メッシュベルト幅:1500mm ステンレスファン:6*1.5kw メッシュベルトモーター:シーメンス PLC: シーメンス SUS 304 内箱厚さ:0.8mm 外厚:0.8mm 内側の断熱綿;120mm コンプレッサーブランド:ドイツBitzer 材質:304SUS |

自動フライドポテト生産ラインの機能:

- 自動フライドポテト生産ラインは労働力を節約し、ライン全体を操作するのに必要なのは 4 ~ 5 人だけです。

- フライドポテトを低コストで製造します。原材料はジャガイモで、価格が低く、リサイクルコストがより速くなります。

- チップ処理機は省電力モーターを使用して電力を節約し、生産コストを削減します。

- フライドポテトの生産ライン全体が低燃費で、揚げ温度も調整可能です。

- 容量:300〜1000 kgの完全自動生産ライン出力は、顧客のニーズに応じて適切なマシンと一致します。

- フライドポテトマシンの高度な機械構成と制御。常に安全な作業状態を保つことができ、生産量の向上だけでなく、製品の品質も安定します。最終製品の色、香り、味が統一されます。

- 生産ラインの連続フライヤーの自動濾過により、油の耐用年数を大幅に延ばすことができます。オイルを頻繁に交換する必要はありません。製品の揚げ工程で消費する油と製品が吸収する油が同等となり、油の利用効率が大幅に向上します。

- 高度で効率的な加熱システムはエネルギーの無駄を避け、エネルギー消費を大幅に節約します。生産ラインの継続的な作業により、作業効率が向上し、コストが効果的に削減され、人件費と管理費の面でも非常に役立ちます。

- この装置の使用により、製品の品質が大幅に向上し、生産プロセスにおけるさまざまなコストが削減され、製品の市場競争力が高まります。

自動冷凍チッププラント特に加工

- 価格(価格面では同業界の中では当社のほうが有利です。ご購入量が比較的多い場合は、元の価格から多少の割引もさせていただきます)

- 使用期間(適切なメンテナンスを行った場合、使用期間は5~6年)

- 作業効率(単位時間当たりの生産量が高く、200~500kg/h、500~800kg/h、800~1000kg/h。お客様のさまざまなニーズに応じて、さまざまな容量の機械設備を装備することができます)

- 耐荷重(300~1000kg)