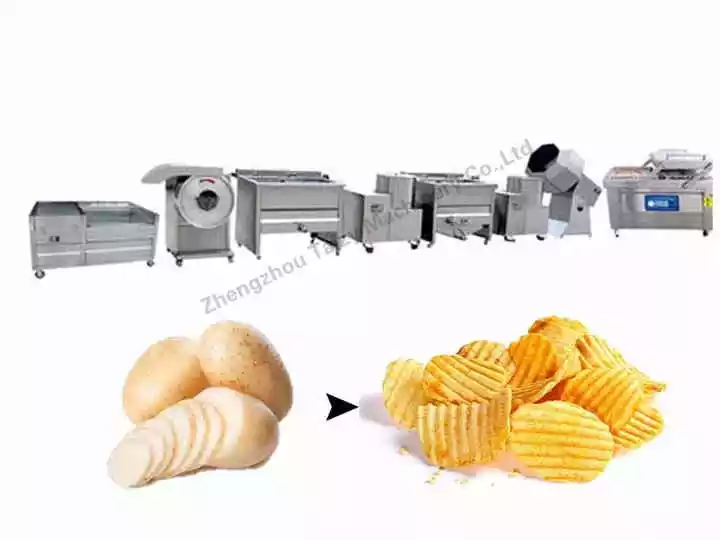

100 kg Mini-Kartoffelchips-Pflanze

Bei einer kleinen Produktionslinie für Kartoffelchips beträgt der Ausstoß etwa 50 bis 500 kg/h. Wenn die 50 kg Mini-Kartoffelchips-Anlage Ist für Erstinvestoren geeignet, dann erweitert die 100-kg-Kartoffelchips-Linie ihre Produktion. Für kleine und große Kartoffelchipslinien stehen sowohl Elektro- als auch Gasheizmethoden zur Auswahl.

Die Kartoffelchip-Produktionslinie verändert die Art und Weise der Kartoffelchip-Produktion

Die ersten frittierten Kartoffelchips entstanden durch einen Unfall. Kapitän Vanderbilt beschwerte sich beim Koch, dass die Kartoffelchips zu dick seien. Der Koch schneidet die Kartoffeln in hauchdünne Scheiben, frittiert sie und bestreut sie anschließend mit Gewürzen. Bisher wurden frittierte Kartoffelchips in verschiedenen Regionen verbessert und bildeten nach und nach die heutigen frittierten Kartoffelchips. Die ersten frittierten Kartoffelchips wurden natürlich von Hand hergestellt. Mit der Beschleunigung der Industrialisierung hat das Aufkommen automatisierter Maschinen diese Produktionsweise verändert. Die Herstellung von Kartoffelchips begann sich in Richtung Automatisierung zu entwickeln.

Warum brauchen wir eine Mini-Kartoffelchips-Anlage?

Handgefertigte frittierte Kartoffelchips weisen nicht nur eine geringe Produktionseffizienz auf, sondern weisen auch ungleichmäßige Schnittgrößen und schlechte Formen auf. Das Mechanisierte Produktionslinie für Kartoffelchips nutzt intelligente Maschinen für die Herstellung von Kartoffelchips. Kommerzielle Kartoffelchip-Schneider schneiden Kartoffeln in gleichmäßige Dicke und gleichmäßige Dicke. Die elektrisch oder gasbeheizte Kartoffelchip-Fritteuse kann die Temperatur und die Frittierzeit während des Frittiervorgangs steuern. Die Mini-Kartoffelchip-Anlage verbessert nicht nur die Produktionseffizienz von Kartoffelchips, sondern wandelt die Kartoffelchip-Produktion auch in eine groß angelegte Industrialisierung um.

Konfigurationsliste für 100 kg/h Gas-Mini-Kartoffelchips-Anlage

| Artikel | Bild | Details |

| Wasch- und Schälmaschine |  | Modell: TZ-800 Kapazität: 600 kg/h Abmessung: 1600*850*800 mm Spannung: 220 V, 50 Hz Leistung: 1,1 kW Gewicht: 180 kg Eine Charge: 2 Minuten Material: Edelstahl 304 Rollen: 9 Stück Maschine mit Rädern, Sprays, Wasserschale. |

| Schneidemaschine |  | Modell: TZ-600 Gewicht: 110 kg Leistung: 1,1 kW Größe: 950 * 800 * 950 mm Kapazität: 600 kg/h |

| Blanchiermaschine |  | Modell: TZ-700 Gewicht: 320 kg Größe: 1500 * 800 * 1000 mm Heizungsart: Gas Kapazität: 100 kg/h 50 kg/Charge (2 Rahmen) Material: Edelstahl 304 Eine Charge: 1-2 Minuten Entfernen Sie die Stärke |

| Dörrgerät |  | Modell: TZ-900 Kapazität: 300 kg/h Größe: 1000 * 500 * 700 mm Spannung: 220 V, 50 Hz Leistung: 1,5 kW Gewicht: 360 kg Material: Edelstahl 304 Zeit: 1-3 Minuten Funktion: Nach dem Blanchieren der Kartoffel befindet sich auf der Oberfläche Wasser, sie kann nicht direkt gebraten werden, daher muss diese Maschine zum Entfernen des Wassers verwendet werden. Sie können die Zeit selbst einstellen |

| Frittiermaschine |  | Modell: TZ-700 Gewicht: 320 kg Größe: 1500 * 800 * 1000 mm Kapazität: 100 kg/h Material: Edelstahl 304 Heizungsart: Gas Frittierzeit: 40–60 Sekunden Ölkapazität: 100L Brattemperatur: 160–180 Grad Funktion: Frittieren der gefrorenen Pommes frites/Kartoffelchips. Die Frittiermaschine verfügt über einen Behälter für kontrollierbare konstante Temperatur und gleichmäßige Erwärmung. 2. Die Rückstände im Frittieröl werden automatisch herausgefiltert, um sicherzustellen, dass das Öl sauber ist und verwendet werden kann für eine lange Zeit. |

| Entölungsmaschine |  | Modell: TZ-900 Kapazität: 300 kg/h Abmessung: 1000 * 500 * 700 mm Spannung: 220 V, 50 Hz Leistung: 1,5 kW Gewicht: 360 kg Material: Edelstahl 304 Funktion: Nach dem Frittieren von Kartoffelchips verwenden Sie diese Maschine, um das Oberflächenöl zu entfernen, und gehen Sie dann zur Gefriermaschine. |

| Gewürzmaschine |  | Modell: TZ--800 Gewicht: 130 kg Leistung: 1,5 kW Kapazität: 300 kg/h Material: Edelstahl 304 Einfaches Design, kostensparend, beeinträchtigt jedoch nicht die Produktionsfunktion und -effizienz. |